Cellulose: The Perfect Insulation

One Material Multiple Methods

Whether it’s dense-pack, damp-spray, loose-fill, or made into batts or blankets, all cellulose insulation starts with the same raw material: recycled paper. Most manufacturers use recycled newspaper (80% to 85% by weight) to make cellulose insulation, although new start-up UltraCell (ultracellinsulation.com) is working on cellulose made primarily from recycled cardboard, which is less dusty than newspaper. The remaining 15% to 20% of the cellulose mix is boron compounds, which act as a fire retardant and pest deterrent. Some products substitute ammonium sulfate, sodium sulfate, or magnesium sulfate for some of the boron compounds. These sulfates are

less expensive fire retardants, but there are some claims of an unpleasant odor and possible corrosion issues when exposed to moisture.

The R-value

The R-value of cellulose is based mainly on its installed density, with denser installations generally

delivering higher R-values. Loose-fill cellulose has an R-value of R-3.7 to R-3.8 per in., while damp-spray and dense-pack assemblies are rated at R-3.6 per in. or higher depending on its installed density. The difference in appearance between a proper dense-pack installation and one with a lower R-value that is prone to settling or air leaks is tough to spot in existing construction, so you should ask for empty bag counts from the insulation contractor. Knowing the weight and number of bags blown and then doing some quick math to determine the density of the installed insulation will ensure you’re getting a quality job.

Fire control

Cellulose insulation is so fire-resistant you can melt a penny with a propane torch while it sits on

a handful of cellulose and the material will be only slightly charred. Its performance during a fire is

backed up by its Class 1/Class A fire rating (it has a flame-spread rating of 15 or less and a smokedeveloped index of 5 or less). These properties mean that cellulose will smolder, but it won’t

burn without applying a high-temperature flame. Nu-Wool and other manufacturers offer over 50 UL-listed fire-rated assemblies, some providing up to three hours of fire resistance.

Air control

Cellulose is not technically an air barrier on its own, although at sufficient densities it can slow air movement enough to meet the envelope airtightness requirements of the 2012 IRC (3 ACH50 for most climate zones) without an additional air barrier. Cellulose’s air-sealing qualities are especially useful in retrofit work where existing walls are left intact and the cellulose is installed though holes made in the home’s exterior or interior. Cellulose is also less affected by wind-washing—a condition where air moving past the insulation reduces its insulating ability—than unprotected fiberglass batts or blown-in fiberglass.

Sound control

Cellulose performs well in assemblies meant to minimize sound because its small fibers fill the voids that transmit high-frequency sound and its density helps dampen lower frequencies. One maker’s testing shows that a cellulose-insulated 2x4 wall spaced 16 in. oncenter with no exotic sound-control measures (only cellulose and airsealing) could achieve an STC (sound transmission class) of 41, and a double-stud wall could reach STC-61, which is virtually soundproof. According to the same company, a typical wall insulated with fiberglass batts is STC-39.

Water resistance

Due to its unique makeup, cellulose has a helpful relationship with water. It can take on and release moisture seasonally as it pulls moisture away from framing and sheathing. Research done by Building Science Corp., a leader in building science and technology, found that although computer modeling predicted high moisture levels and data loggers confirmed this on a superinsulated project in Western Massachusetts, when they opened the walls they found no evidence of damage.

Environmental impact

According to the Cellulose Insulation Manufacturers’ Association, cellulose production diverts almost one-million tons of paper waste from landfills annually in the United States, and insulating a single 1,500-sq.-ft. house with cellulose will recycle as much newspaper as an individual will consume in 40 years. As long as the recycled content is at least 10% (it usually is) and is manufactured within 500 miles (there are a lot of manufacturers spread throughout the country), cellulose insulation is worth LEED points and the NAHB’s Green Building Program points.

Mold/fungus resistance

Testing conducted by Building Science Corp. found no evidence of mold or fungal growth in cellulose insulation, even when environmental conditions are conducive to growth (meaning 100% relative humidity and temperatures above 50°F.) A four-year study conducted at Truman State University found that even a 5% borate treatment was enough to effectively halt mold and fungal growth, and cellulose includes even higher percentages of borates (in the range of 15% by weight) in order to meet fireresistance requirements.

Sprayed Cellulose

Cellulose insulation combines the ease of installation with superior thermal and acoustical performance making them a smart choice for owners and contractors.Acoustical Test

Rooms are noticeably quieter with Cellulose Insulation, which deadens the transfer of sound from one room to anotherCellulose Insulation Provides a Green, Efficient, Non-Toxic Thermal Solution

-

Save up to 40% on power bill

-

Reduces noise by 80%

-

Easy To Install

-

Kills Mold And Fungus

-

Insect And Rodent Repellant

Supporting Documents

(1 MB)`EcoFibra-UL-Evaluation-Report

(255 KB)`TECHNICAL DATA SHEET

(621 KB)`Total green product nothing harmful

(38 KB)`Glue Spec

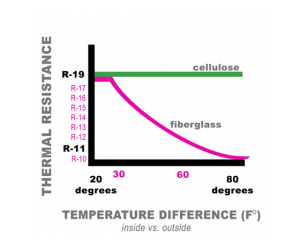

The thermal protection of a home is essential; controlling durability, cost of operation and property owners and tenants' comfort. Fiberglass insulation is the standard bearer. The ubiquitous bales of pink and yellow fiberglass insulate more than 90% of the new homes built in the United States. But thanks to advances in technology we have new and better alternatives.

The common standard by which insulation is measured, R-value, is the level of resistance to heat flow. R-value measures conductive resistance – the ability of a material to impede the flow of heat along the continuous chain of matter that makes up a solid material. Most of a home’s heat is typically lost through conduction. Cellulose is not unusual in this regard. Like many insulation materials, it provides an R-value of approximately R-3.8 per inch of thickness. But, air leakage through cracks, voids, and gaps is important, responsible for approximately one-third of an average home’s heat loss. Cellulose is a superb air-blocker. Heat and comfort are also lost through convection; when drafty currents of air within the house, wall cavities or attics, move heat to other locations. Tightly packed cellulose provides a thermally efficient, cost effective, and comfortable solution.

Thermal performance

The thermal performance of cellulose insulation compares favorably to other types of low cost insulation. The thermal conductivity of loose-fill cellulose is approximately 40 mW/m·K (an R-value of 3.8 per inch). This doesn’t represent the whole picture of thermal performance. Other important aspects are how well the building envelope is sealed from air infiltration, convective airflows, and thermal bridging.

The thermal performance of cellulose insulation compares favorably to other types of low cost insulation. The thermal conductivity of loose-fill cellulose is approximately 40 mW/m·K (an R-value of 3.8 per inch). This doesn’t represent the whole picture of thermal performance. Other important aspects are how well the building envelope is sealed from air infiltration, convective airflows, and thermal bridging.

Cellulose is very good at fitting around items in walls like pipes and wiring, leaving few air pockets that can reduce the overall efficiency of the wall. Dense pack cellulose can seal walls from air infiltration while providing the density to limit convection, when installed properly. The University of Colorado School of Architecture and Planning did a study that compared two identical test structures, one insulated with cellulose and the other with fiberglass. The cellulose insulation lost 26.4% less heat energy over time compared to the fiberglass insulation. It also was shown to tighten the structure more than 30%. Subsequent real world surveys have cellulose performing 20-30% better at reducing energy used for heating than fiberglass.

Six inches of blown in Cellulose insulation is all it takes to prevent the loss of heat due to air convection versus fiberglass alone. Even if you have fiberglass installed in your attic, you can improve its performance by providing a “cap” of Cellulose insulation six inches deep, which will save you money on your utility bills.

The Applications

Dry Cellulose (Loose Fill)

Dry Cellulose is generally blown into new or existing walls or ceilings. During installation by this method, the material will settle by as much as 20 per cent and must therefore be permanently supported.

Spray On Cellulose (Wet Spray)

Spray applied cellulose is used for insulating new stud framed walls (drywall) or ceilings during construction. The only difference between this application and the dry cellulose method is the addition of water, and sometimes with an adhesive, to the cellulose while spraying. Wet spraying helps seal cavities against air infiltration and eliminates settling problems.

Cellulose Panels (Batts)

Celulose panels are commonly installed in sidewalls of residential or commercial structures, but can also be installed in rim joists, attics, floors or other hard to insulate areas. They are also very functional where traditional loose fill or sprayed-in cellulose insulation is not practical

Sound Transmission Class (STC) Charts

Sound Transmission Class (STC) Rating

| Building Component | STC |

|---|---|

| 1/4-inch plate glass | 26 |

| 3/4-inch plywood | 28 |

| 1/2-inch gypsum board, both sides of 2x4 studs | 33 |

| 1/4-inch steel plate | 36 |

| Concrete block: Autoclaved aerated | 45 |

| 3-inch concrete wall | 47 |

| 6-inch reinforced concrete slab (4-1/8" thick) | 44 |

| 6-inch concrete block wall | 42 |

| 8-inch reinforced concrete wall | 51 |

| 12-inch concrete block wall | 53 |

| 12-inch brick | 56 |

| 2x4 wood studs (16" o.c.) with 1/2" GWB both sides | 33-39 |

| 1-5/8" inch steel studs (24" o.c.) with 1/2" GWB both sides | 39 |

| 3-5/8" inch steel studs (24" o.c.) with 1/2" GWB both sides | 40-44 |

Changes in STC and Apparent Loudness

| Changes in STC Rating |

Changes in Apparent Loudness |

|---|---|

| +/- 1 | Almost imperceptible |

| +/- 3 | Just perceptible |

| +/- 5 | Clearly noticeable |

| +/- 10 | Twice (or half) as loud |

| STC | Privacy Afforded |

|---|---|

| 25 | Normal speech easily understood |

| 30 | Normal speech audible but not intelligible |

| 35 | Loud speech audible and fairly understandable |

| 40 | Loud speech audible but not intelligible |

| 45 | Loud speech barely audible |

| 50 | Shouting barely audible |

| 55 | Shouting not audible |

| 60+ | Superior soundproofing; most sounds inaudible |

STC Guidelines for INSU-GREEN Cellulose Insulation

General guidelines for controlling noise between spaces:

- INSU-GREEN cellulose insulation outperforms all other insulation systems for sound attenuation. In a typical 2 x 4 wall with a single layer of 1/2” drywall on each side (Tested STC):

- INSU-GREEN cellulose STC 41

- Fiberglass or mineral fiber STC 38

- Icynene STC 37

- The installed performance in batt insulation systems is typically well below that of their tested STC values

- Metal studs perform better than wood studs by about 5db.

- Staggering the studs or using dual studs can provide a substantial increase in sound isolation.

- Increasing the size of the air space in a wall or window assembly will improve its sound isolation.

- Resilient channel can improve the STC ratings of an assembly and is necessary to improve the Impact Insulation Class “IIC” in floor / ceiling assemblies.

- A wall must extend to the structural deck in order to achieve optimal isolation. Walls extending only to a dropped ceiling will result in poor sound isolation.

- Sound will travel through the weakest structural elements, which, many times, are doors, windows or electrical outlets.

The STC of wall assemblies filled with INSU-GREEN cellulose insulation can be estimated by using the table below. Start with an uninsulated 2 x 4 wall and than add the other components to achieve the overall STC for the wall assembly.

STC Additive Estimator for Cellulose Walls

| STC | Wall Component |

|---|---|

| 27 | Starting Wall: Uninsulated wood studs 2 x 4 16" o/c |

| +3 | Studs 24" o/c |

| +5 | Metal studs |

| +3 | 1/2" Gypsum |

| +4 | 1/2" Type X gypsum |

| +4 | 5/8" Gypsum |

| +5 | 5/8" Type X gypsum |

| +2 | 3/8" Plywood |

| +3 | 1/2" Plywood |

| +4 | 5/8" Plywood |

| +3 | 3/8" OSB |

| +4 | 1/2" OSB |

| +5 | 5/8" OSB |

| +8 | 3 1/2" INSU-GREEN Cellulose |

| +14 | 5 1/2" INSU-GREEN Cellulose |

| +3 | Resilient Channel |

Nu Wool Products

Established in 1949, Nu-Wool Co., Inc. manufactures environmentally friendly cellulose insulation materials. Nu-Wool Premium Cellulose Insulation is a superior product designed for use in walls, attics and floors of new and existing residential and commercial structures. Made from recycled paper, Nu-Wool Premium Cellulose Insulation has superior thermal and air-infiltration properties, creates quiet and draft-free buildings, and saves on energy bills*. The performance of Nu-Wool Premium Cellulose Insulation is backed by our industry-leading 10-year Energy Guarantee on new construction homes insulated with Nu-Wool. Driven by our commitment to manufacturing quality products, and providing unparalleled technical support and customer service, Nu-Wool Co., Inc. is the longest running cellulose insulation manufacturer in the world. When it comes to choosing insulation, Nu-Wool Premium Cellulose Insulation is not only the GREEN choice, but also the superior choice.

Supporting Documents

(263 KB)`Nu Wool - English

(80 KB)`Nu Wool - Español

(402 KB)`Nu Wool Factsheet

(418 KB)`Nu Wool Project Profile

(592 KB)`Licencia de los Bomberos